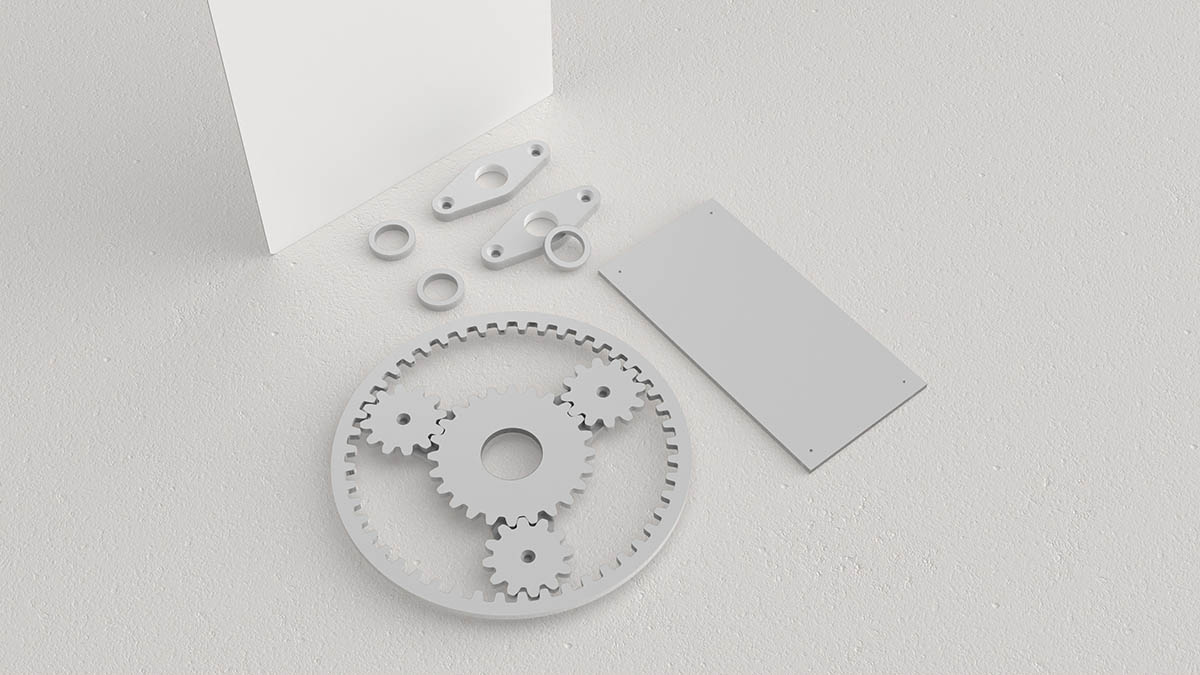

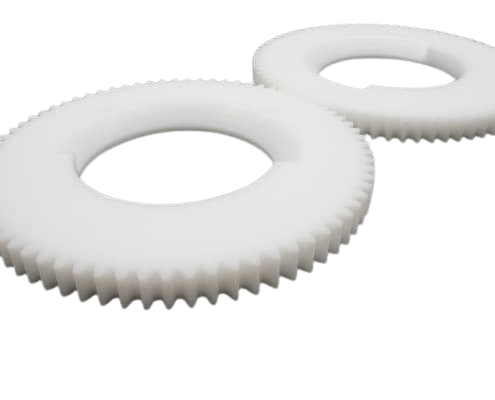

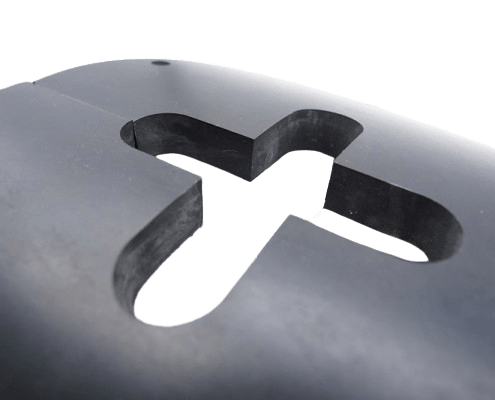

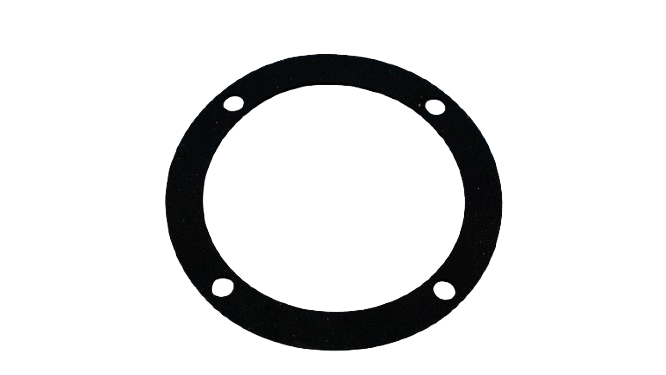

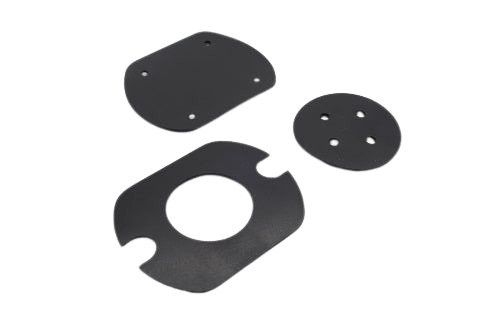

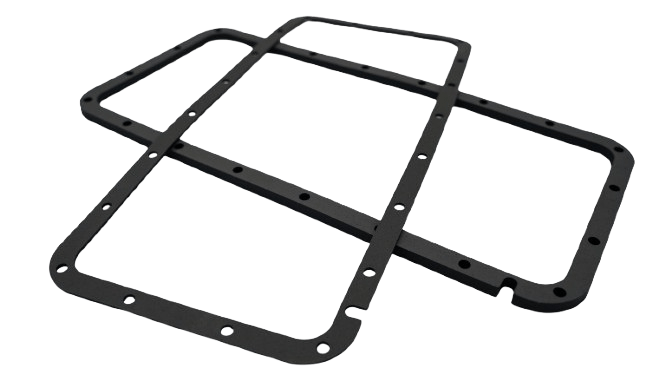

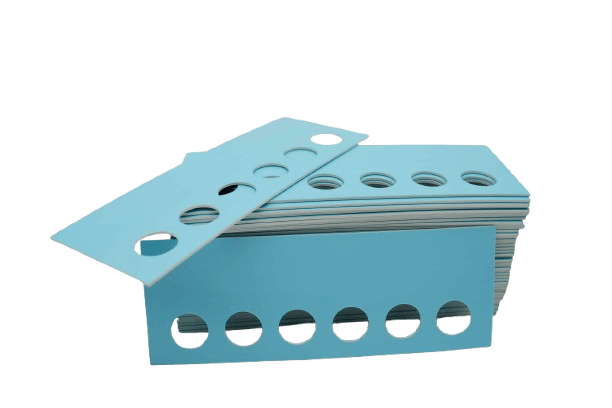

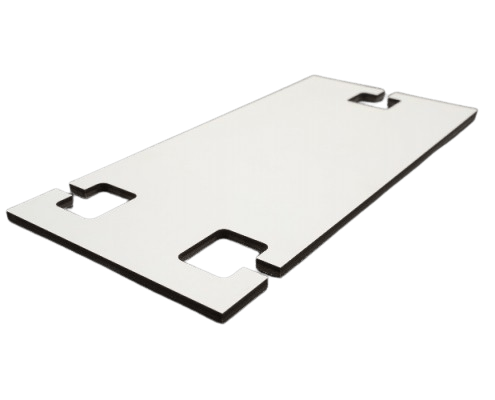

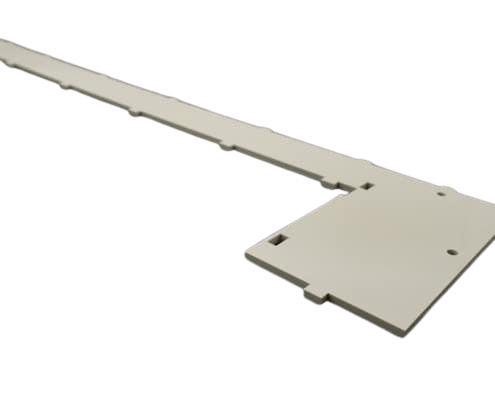

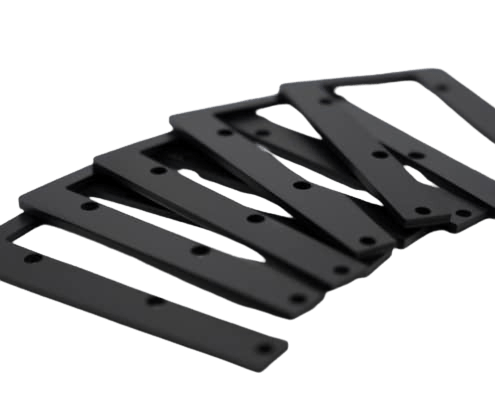

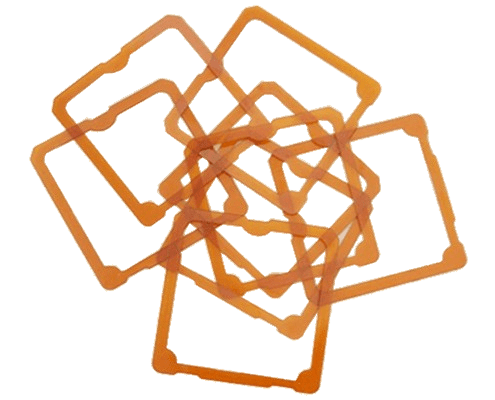

PTFE (Teflon®)

Plastic

PTFE, better known by the brand name Teflon®, is a plastic distinguished by its exceptional chemical resistance and extremely low coefficient of friction. Thanks to its high temperature resistance and excellent insulating properties, PTFE is ideal for demanding environments. Moreover, the material is non-stick, making it widely used in technical applications where an anti-adhesion effect is required.

Well-known trade names for PTFE include Teflon®, Dyneon™, Fluon®, and Hostaflon®. These variants are used worldwide for their reliable performance in industry.

- Laser cutting

- Milling